THE JML Difference

NADCAP approved since 1994

Largest laboratory of its kind with 300 test stands capable of stress-rupture, creep, and creep-rupture testing from room temperature to 2000 degrees Fahrenheit

Uniquely qualified to test the most advanced materials including single crystal alloys

Utilization of a continuous looped system to control test temperature per ASTM and allow verification of each test

Application of dual measuring instrumentation extensometers with computer averaging for greater precision at low strain rates

Specialization in long term, greater than 5 year, creep and stress-rupture testing. JML's instrumentation and measurement avoids the "drift" associated with all electronic LVDT and capacitance transducers

Automatic electrical back up systems in event of power failure

Industries Served

Aerospace

Automotive

Forging and Casting

Gear

Government

Medical

Military

Power Generation

Laboratory TestinG

All testing is performed in accordance with AMS and/or ASTM specifications, unless the customer indicates testing is to be conducted to meet their own specifications. AMS specifications are updated quarterly and ASTM standards are updated on an annual basis. Current material specifications are kept current as received from the customer. In the case of testing to either AMS or ASTM or customer specifications, the customer is advised of any test that fails to meet minimum requirements. Testing results are available in both hard copy and digital formats.

Laboratory Services

Low Stress Ground Specimen Preparation

Tensile Testing - NADCAP approved with temperatures available from room temperature to 2000 degrees Fahrenheit

Stress-Rupture - NADCAP approved with temperatures available from room temperature to 2000 degrees Fahrenheit

Creep and Creep Rupture - 300 NADCAP approved test frames with temperatures available from room temperature to 2000 degrees Fahrenheit

What is a Creep Test?

At Joliet Metallurgical Laboratories we specialize in long term creep and creep rupture testing. Creep testing involves analyzing a metal’s ability to withstand a constant force over time at temperatures ranging from room temperature to 2000 degrees Fahrenheit. Our instrumentation allows for accurate readings on the rate of metal deformation under set conditions for a variety of industries. Creep testing is an essential part of the design and fabrication of metals utilized in the aerospace, automotive, power generation, forging and casting industries.

Machine Shop

Full service, NADCAP approved machine shop services featuring an aerospace approved low stress grinding division

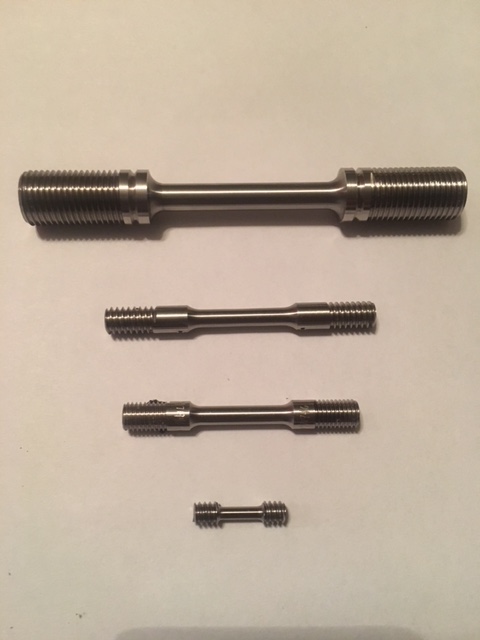

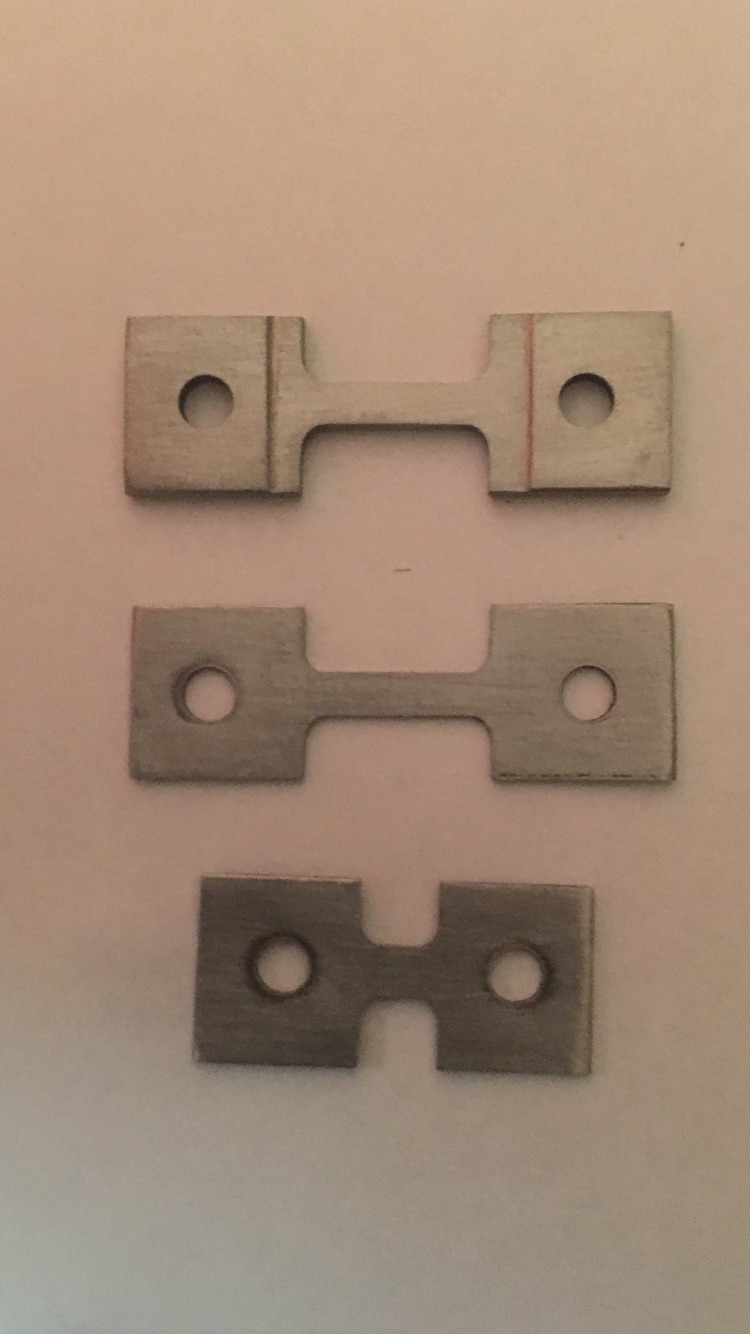

Available for specimen preparation, including bars and sheets, as well as test equipment modification

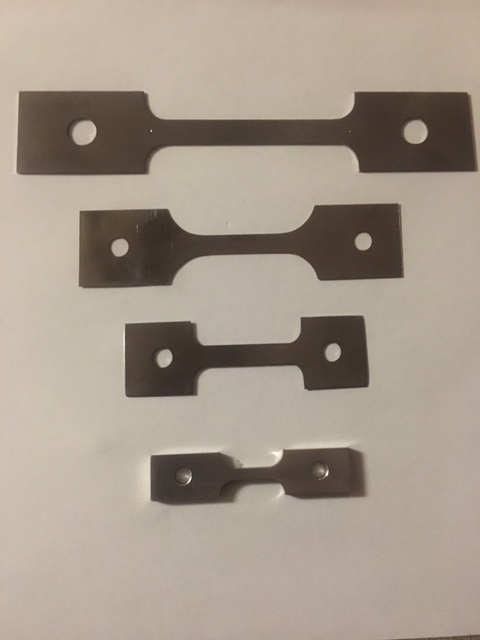

Honeywell approved for miniflat machining

Low speed grinding for all of our bar samples

Machining for various size sheet samples and miniflats

ENGineering consultation

Over 30 years experience in aerospace and land based turbines, oil and gas, mechanical testing and failure analysis